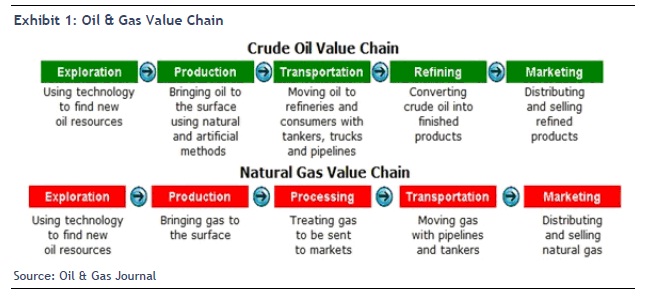

In the midstream sector, raw crude oil & natural gas that is produced and developed from the upstream sector is gathered, processed, transported and marketed to the downstream sector, which consists of end-use customers, wholesalers and local distributors across North America.

Midstream facilities can include gas processing, liquids extraction, gas and liquids storage, and transportation assets. Liquids can refer to crude oil or natural gas liquids (NGLs), such as ethane (C2), propane (C3), butane (C4) and condensate/pentanes (C5).

Condensate is particularly important in Alberta, where it is widely used to dilute oil sands bitumen production, so that it can flow through the pipeline system.

Natural Gas Gathering and Processing

Raw natural gas produced from the upstream sector is typically composed of methane (commonly referred to as “natural gas”) and NGLs. The gas processing plants take “wet” gas and remove the heavier liquids components (NGLs) as well as other contaminants to create marketable “dry” gas, which will only then meet the gas composition restrictions of major transportation pipelines.

Although a by-product in the process, the extracted NGL stream that contains ethane, propane, butane, and condensate is of significant value, and this mixture is subsequently sent to fractionators to be separated into marketable products. Gas producers targeting “liquids-rich” gas are looking for “wet” gas streams that have a significant amount of NGLs entrained. Canadian gas processing economics in the field are generally on a fee-for-service basis. Large extraction plants (also called “straddle plants”) on the main export line often operate under economics that depend on the price of the extracted liquids relative to its equivalent value if left in the original gas. The difference between the price of the extracted liquids and its price of methane (i.e., natural gas) is called the “frac spread”.

Fractionation, Transportation, and Storage

Midstream companies also own and operate infrastructure, including fractionation plants, storage facilities, and rail and truck loading/offloading facilities. The raw NGL-mixed stream from gas processing plants is sent via NGL pipelines or trucks to fractionation facilities that separate the liquids mixture into marketable products (ethane, propane, butane and condensate) that can be used as feedstock for petrochemical plants and refineries, or as heating fuels. These marketable products are transported by various methods to major NGL marketing hubs in North America (e.g., Edmonton, AB; Conway, KS; Mont Belvieu, TX). When supply outweighs demand (often seasonally driven, particularly in the case of propane), gas, oil and NGLs can be stored in either above-ground or underground storage facilities, which provide a ready supply to meet seasonal and operational requirements.

Pipelines

Pipelines are the primary method of transporting natural gas and liquids over long distances from producing regions to end users, such as refineries, which convert crude oil feedstock into endproducts such as gasoline, diesel and other petrochemicals. Gas pipelines are used to transport natural gas from wells to processing plants and distribution systems. Unlike refined petroleum products, natural gas is delivered directly to homes and businesses through an extensive network of smaller diameter distribution pipelines. Please refer to Exhibit 30 for diagrams detailing both crude oil & natural gas pipeline delivery networks.

Liquids Pipelines

Producing oil fields either have a network of small-diameter gathering lines or use trucks to move produced oil from the wells to central facilities, where larger-diameter feeder pipelines transport the crude oil to nearby refineries and to long-haul pipelines. Through these transmission lines, crude oil is transported to more distant refineries, which use various processes to convert crude oil into refined petroleum products such as gasoline. In addition, liquids transmission lines carry other types of liquids in batches, including refined petroleum products and NGLs.

Gas Pipelines

Natural gas producing fields typically have a network of small-diameter gathering lines to move raw natural gas from the producing well to a gas processing facility, which removes water and other components (including NGLs) from the raw gas stream. The “purified” natural gas is then compressed prior to moving into gas transmission pipelines. Compressors placed along the gas transmission pipeline increase the pressure of gas, thereby moving it to its destination, where local distribution companies or gas utilities reduce the pressure for local delivery through smaller distribution pipelines to industrial, commercial and residential customers.

Other

Beginning in 1993, pipelines could no longer sell gas to the end customer who now has to negotiate a price directly with the producer. The pipelines used to take on the risk of a fluctuating gas price but now these risks were passed onto the distribution companies. Interstate pipelines are regulated at the national level by FERC. Most pipelines are not a natural monopoly. There are usually multiple pipelines feeding into a particular region.